Natural Fiber -sustainability engineering

This workshop was the first in enabling rangatahi to explore the use of natural fibre composites as alternatives to synthetic materials. PTC Trust in collaboration with Professor Kim Pickering, John Mcdonald-wharry and the engineering team at University of Waikato were able to offer this workshop to Rotorua girls as we unlocked the science and technology of using jute fibres as the starting block for engineering design.

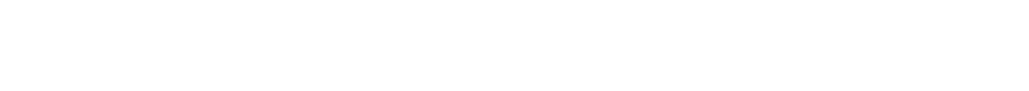

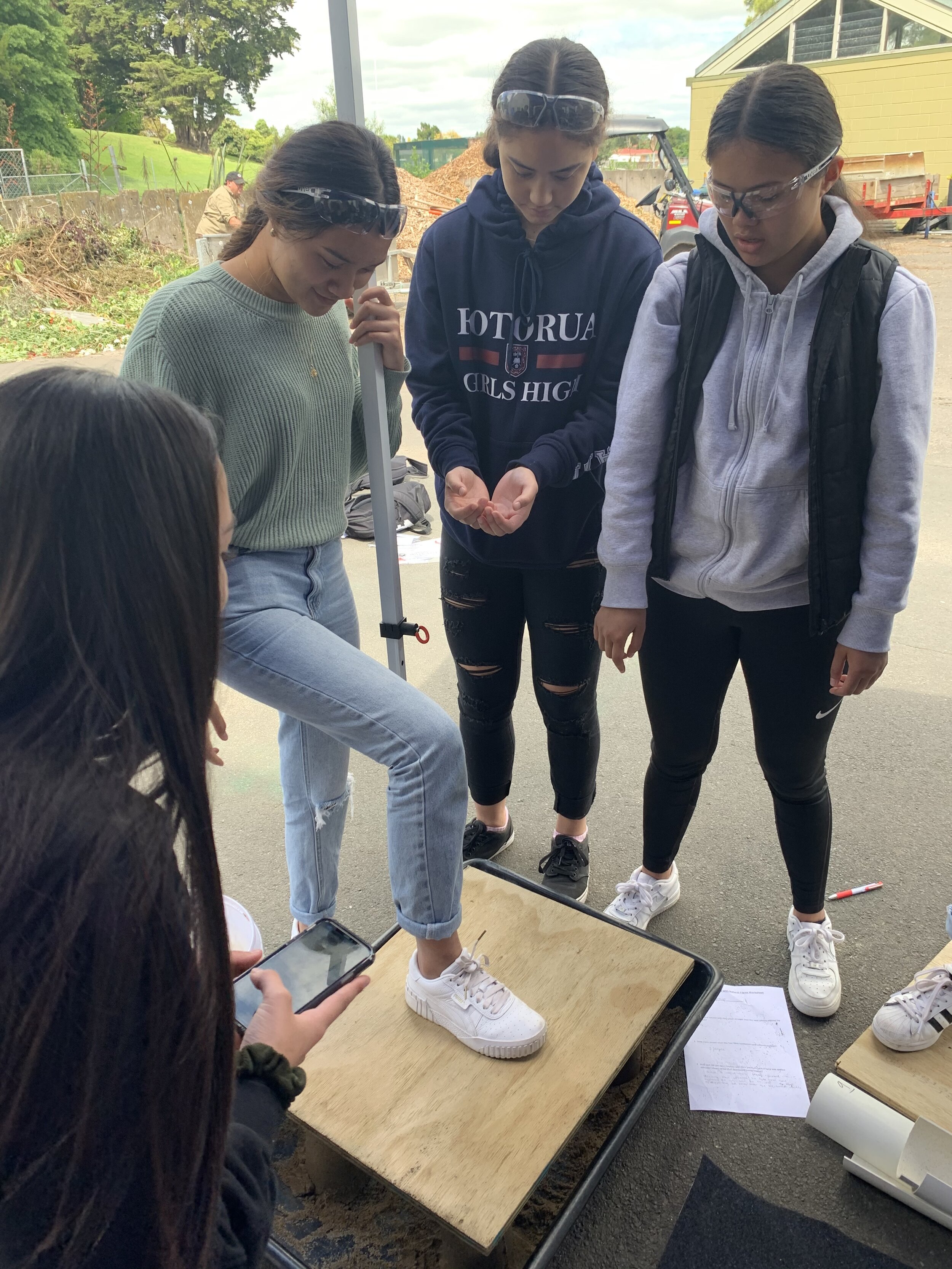

Students gained understanding in three areas

Manufacturing and 3D printing of composite materials (demonstration & display)

Dynamic sheet forming - a method used to produce aligned short natural fibre mats.

Tensile testing – using pre-prepared samples

Pickering (2016) et al describes that ‘there has been a rapid growth in research and innovation in the natural fibre composite (NFC) area. Interest is warranted due to the advantages of these materials compared to others, such as synthetic fibre composites, including low environmental impact and low cost and support their potential across a wide range of applications. Much effort has gone into increasing their mechanical performance to extend the capabilities and applications of this group of materials’.

This workshop focused on the use of Jute fibres in manufacturing composite materials ,from Science direct links.

Jute fibers are:

‘totally biodegradable and recyclable materials, i.e., environmentally friendly materials.

have good insulating properties for both of thermal and of acoustic energies with moderate moisture regain and no skin irritations.

The current annual worldwide production of jute fiber is about 3.2 million tons and used for various applications.

Bag cloth industry is the biggest consumer of jute fibers available in the markets.

Jute bags have gained an advantage as being an eco-friendly option instead of both of nonbiodegradable poly bags that are made from petroleum and paper bags that require large quantities of wood’.

Very good first steps were made as students gained hands-on experience of materials testing and learning how reinforcement with natural fibres can improve strength and stiffness of materials which are flexed (flexural loading).

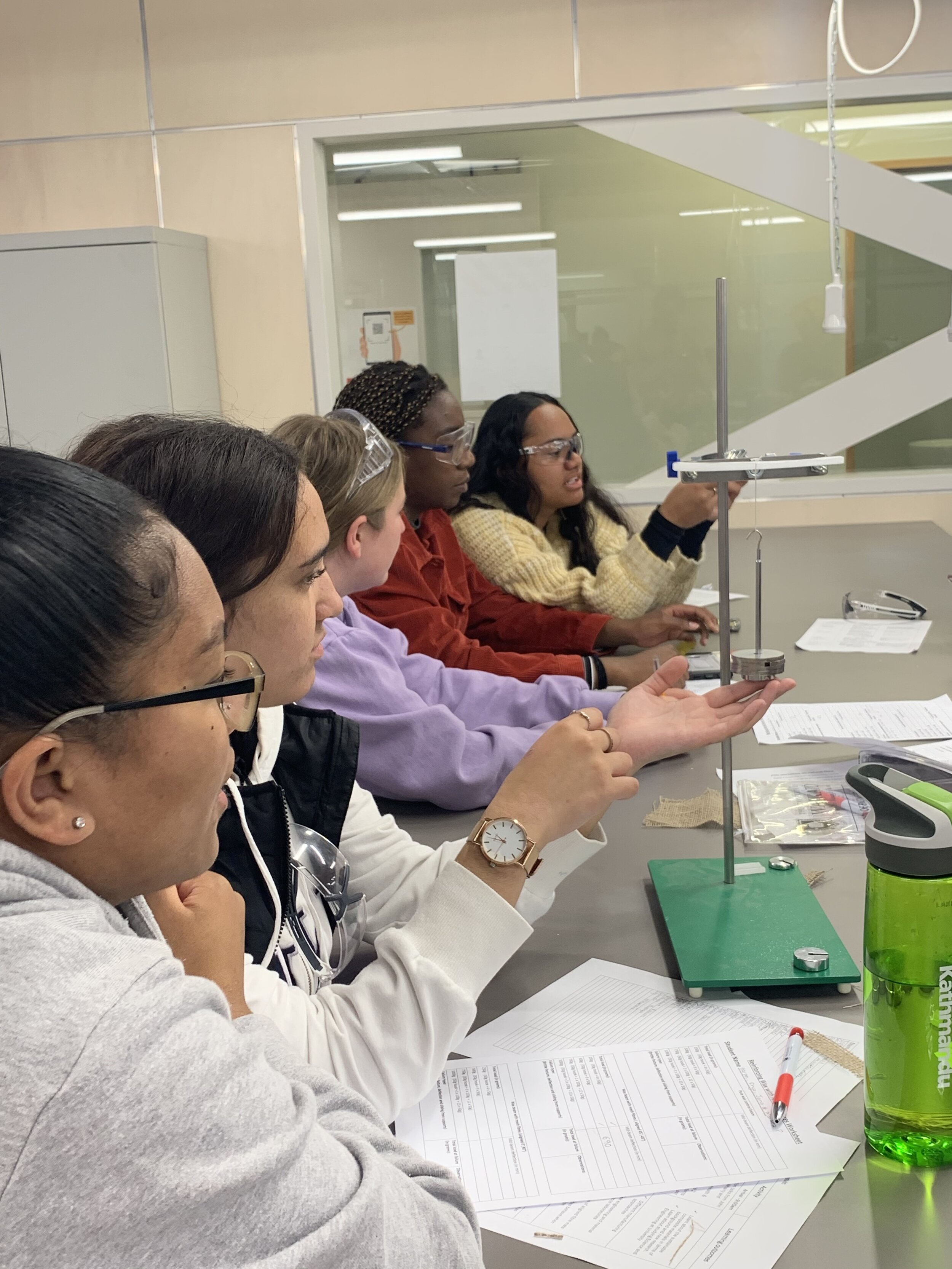

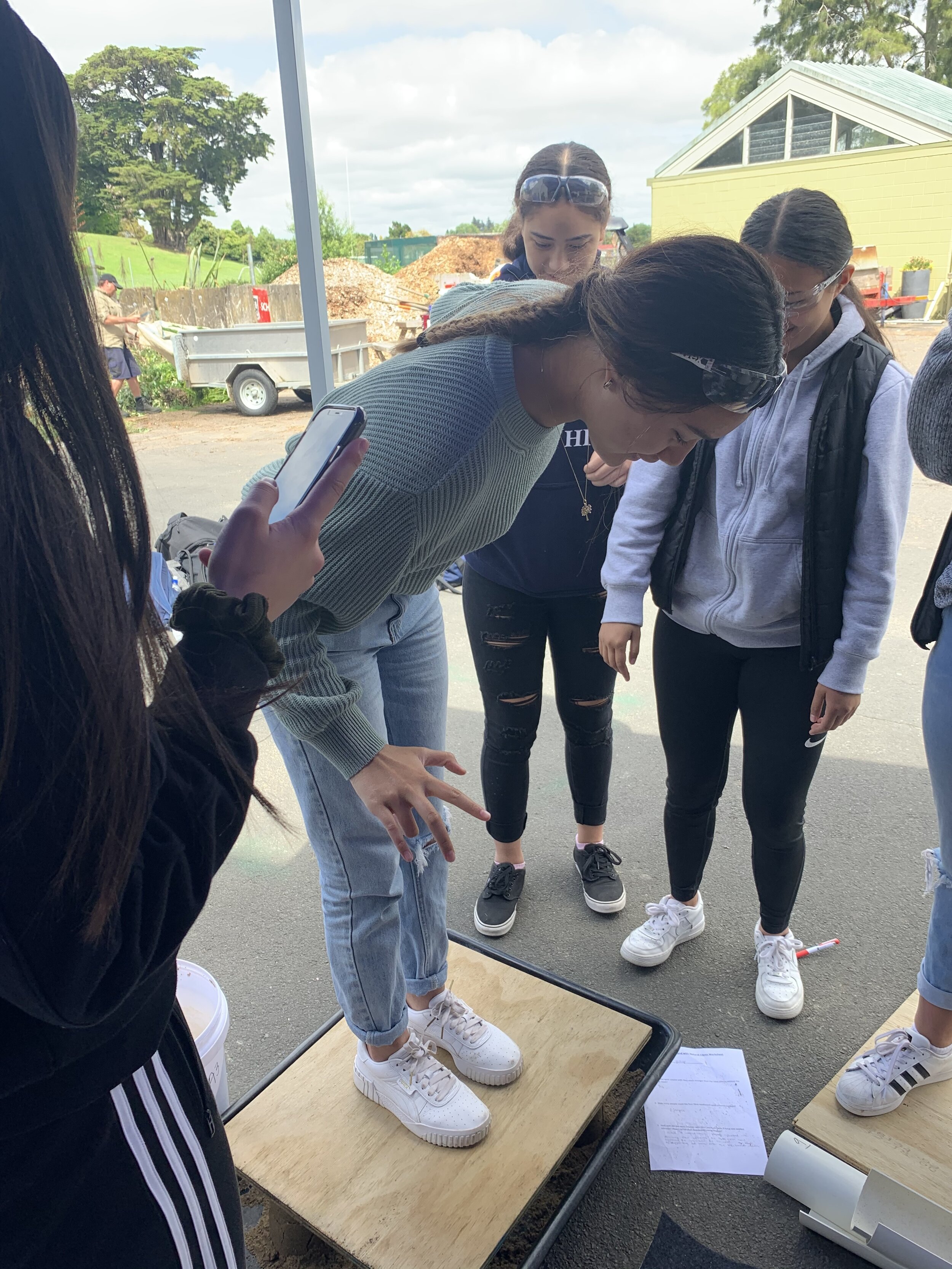

The highlight for the girls were the the ‘sand cake’ activity (Compression testing) in which they had to stand on the plywood placed at the top of the sand cakes.

Initial apprehension and caution, quickly turned to willingness and eagerness as students gained understanding of the effect of natural fibre reinforcement on materials.